Technological database development

Magnesium database

Elements: Mg, Al, Ba, Ca, Mn, Si, Sr, Zn

Some standard applications: Mg-alloys of the AZ-series: Calculation of phase stabilities and phase compositions, evaluation of microsegregation, precipitation simulation.

Special simulations: Phase stabilities and precipitate evolution in special creep-resistant Mg-alloys for automotive applications, phase stabilities and precipitate evolution in bio-degradable Mg-alloys for medical applications.

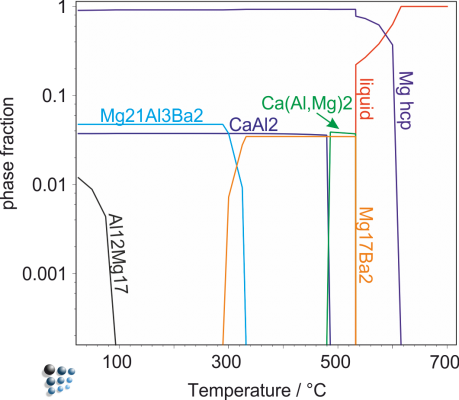

Figure 1. Calculated equilibrium phase fractions for Ba-Al-Ca-containing precipitation-strengthened Mg-alloy (Ba is added for improved creep resistance).

Magnesium High-strength low-alloy

Elements: Mg, Zn, Ca

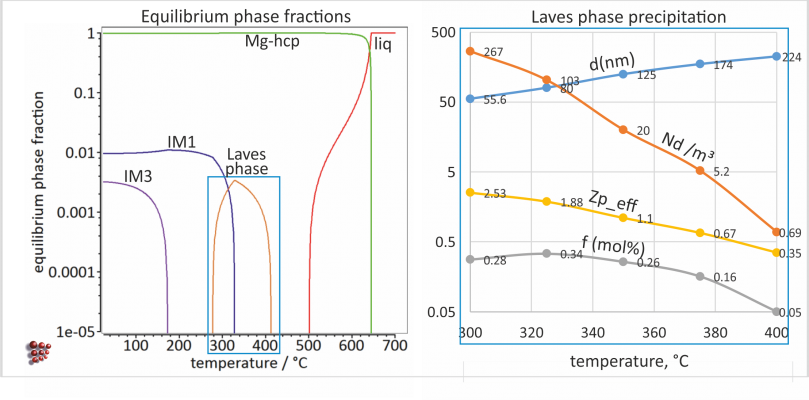

The thermodynamic database has been used for precipitation simulations in biodegradable Mg-base material, Hoftstetter et al., Acta Mater. 98 (2015) 423-432

Figure 2. Equilibrium fractions in Mg-1Zn0.3Ca (wt.%), calculated with mc_mg_v2.001

Molybdenum refractory database

Elements: Mo, Hf, Ti, C, O

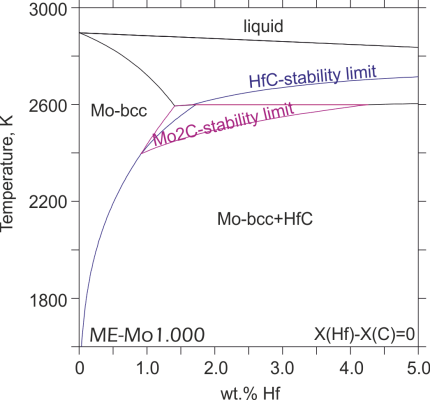

Some standard applications: Determination of carbide and oxide stabilities in powder-metallurgically processed MHC alloy, determination of optimized conditions for solid solution treatment.

Special simulations: Simulation of heterogeneous precipitation, evaluation of the role of oxygen on precipitation.

Figure 4. Quasibinary Mo – HfC diagram at the Mo-rich corner

Shape memory alloys database

Elements: Ti, Ni, Cu, V

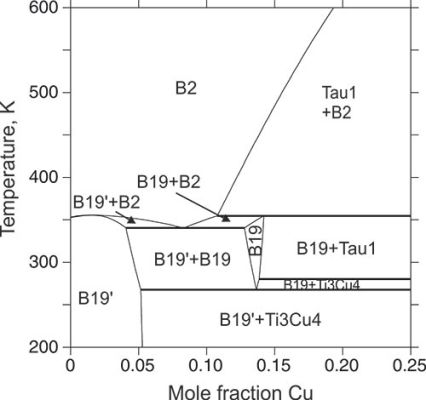

Some standard applications: Evaluation of intermetallic phase stabilities in Cu- or V-alloyed Ti-Ni-base shape memory alloys, determination of solvus temperatures and compositions of metastable precipitate phases.

Special simulations: Evaluating the role of alloying on the martensitic transformation, simulation of time-temperature-precipitation behavior.

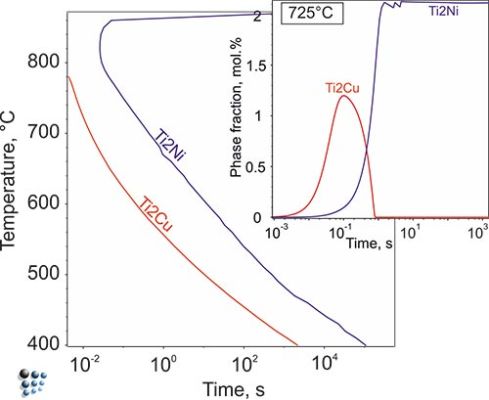

Figure 5. Calculated phase diagram for Ti-Ni-Cu shape memory alloys with varying Cu-alloying. Technologically relevant phase relations between austenitic B2 phase and martensitic B19 and B19´ martensite phases are evaluated.